close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-26 Origin: Site

Twin screw extruders play a crucial role in modern manufacturing, offering superior efficiency and flexibility in material processing. Understanding how a twin screw extruder operates is key to optimizing production processes and ensuring high-quality outputs.

In this article, we will explore the working principles, advantages, and applications of twin screw extruders, giving you a comprehensive understanding of their impact on manufacturing.

A twin screw extruder consists of two intermeshing or non-intermeshing screws housed within a barrel. These screws rotate together, conveying material forward through the extruder. Unlike single screw extruders, twin screw extruders offer enhanced mixing and processing capabilities, making them suitable for a wide range of applications.

● Components of a Twin Screw Extruder:

○ Two intermeshing or counter-rotating screws

○ Barrel that houses the screws

○ Die that shapes the extruded material

The twin screws rotate in either a co-rotating or counter-rotating configuration. The material is fed into the extruder and subjected to high shear forces as it moves through the barrel. These shear forces help in melting, mixing, and homogenizing the material before it is shaped through the die.

● Key Differences from Single Screw Extruders: Twin screw extruders offer superior mixing and processing flexibility due to the combined rotational action of the screws.

Raw materials, typically in pellet or powder form, are fed into the extruder. The two screws convey the material forward, with one screw pushing the material while the other pulls it, allowing for uniform material flow.

● Feeding Mechanism: Material is introduced into the barrel through a hopper and undergoes forced feeding for efficient transport.

As the screws rotate, their intermeshing design enhances the mixing of the materials. This ensures a homogeneous blend, essential for applications that require uniform material properties.

● Shear and Mixing: The high shear forces generated by the rotating screws help break down and blend the materials effectively.

The material is heated as it moves along the barrel. The rotation of the screws generates friction, which, combined with external heaters, melts the material to the desired viscosity for extrusion.

● Controlled Heating: The barrel features several heating zones, which can be independently controlled to adjust the temperature profile of the material.

In co-rotating twin screw extruders, both screws rotate in the same direction. This design enhances material mixing and is ideal for applications requiring thorough blending of polymers or additives.

● Advantages: Higher mixing efficiency, better for material compounding.

In counter-rotating twin screw extruders, the screws rotate in opposite directions. This configuration is suitable for processes that require gentler material handling, such as when working with heat-sensitive materials.

● Advantages: Lower shear forces, better for delicate material processing.

● Intermeshing: The screws engage with each other, allowing for high shear and excellent material mixing.

● Non-Intermeshing: The screws do not engage, resulting in less shear and more gentle material transport.

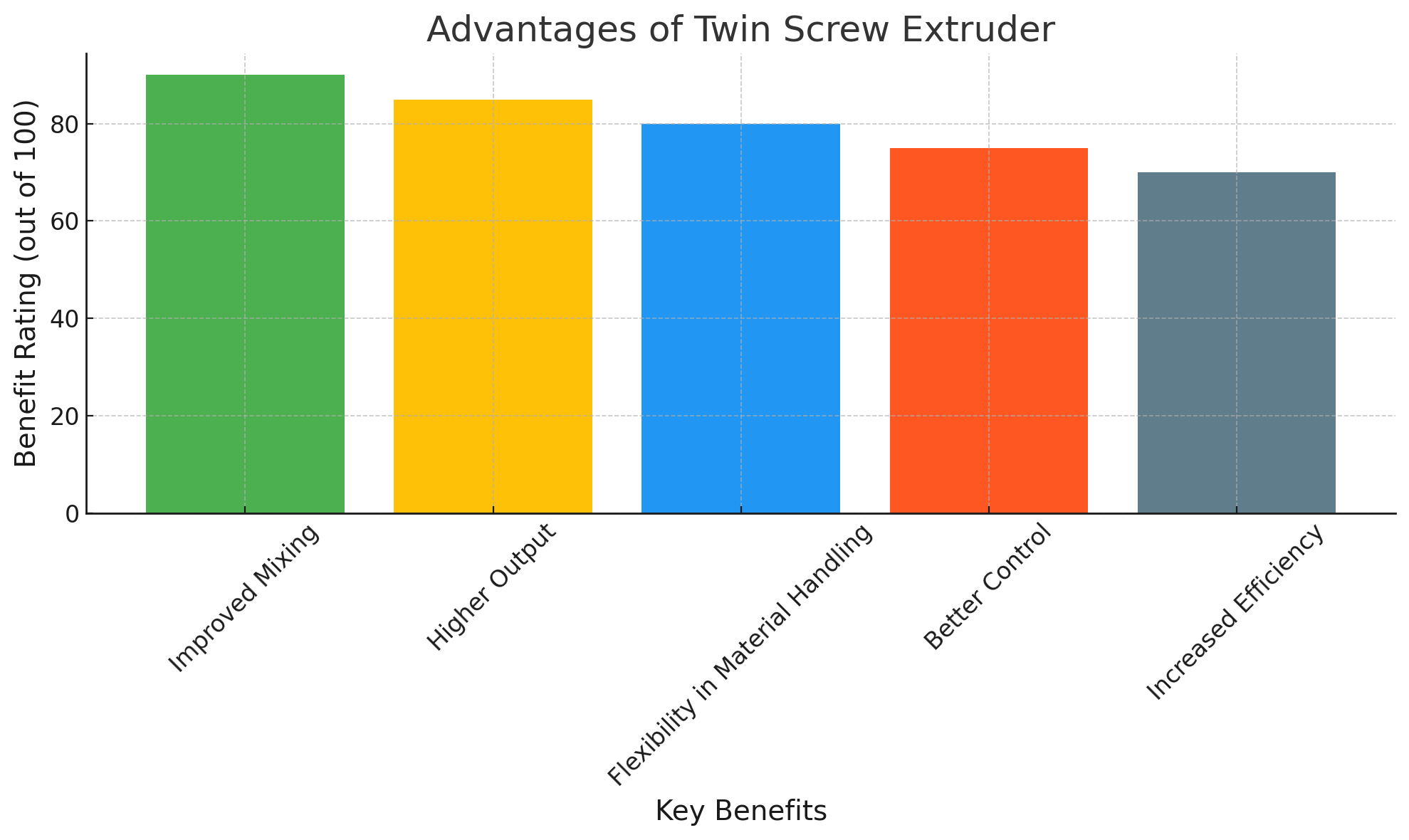

The twin screw design ensures thorough mixing of materials. This is particularly beneficial when processing compounds, masterbatches, or materials with varying viscosities.

● Enhanced Mixing: The intermeshing screws provide superior material blending, eliminating inconsistencies.

Twin screw extruders are capable of processing larger quantities of material compared to single screw extruders. This makes them ideal for high-volume production environments.

● Increased Throughput: The design allows for faster processing and higher output rates.

Twin screw extruders can process a wide range of materials, including those that are difficult to handle with single screw systems. Their versatility allows for the processing of polymers, fillers, and even recycled materials.

● Material Handling: Capable of handling materials with varying viscosities and additives.

With independent control over screw speed, temperature, and shear rate, twin screw extruders offer precise control over the material processing, ensuring consistent product quality.

● Better Process Control: Fine-tuning processing parameters improves product consistency and quality.

Twin screw extruders are widely used in the plastic industry for the production of various products, including pipes, profiles, sheets, and films. Their superior mixing and material handling capabilities make them ideal for these applications.

● Typical Products: Pipes, sheets, films, and wire coatings.

In the food industry, twin screw extruders are used for extrusion cooking, forming snacks, cereals, and pet food. The ability to handle heat-sensitive ingredients makes them particularly useful for food processing.

● Applications: Snack food processing, extrusion cooking, and product formation.

The twin screw extruder plays a critical role in polymer blends, granulation, and resin modification. Their ability to mix and melt materials uniformly is beneficial for producing pharmaceutical compounds and chemical formulations.

● Applications: Polymer blends, granulation, and resin modification.

Twin screw extruders are frequently used in plastic recycling processes. They help melt and reshape recycled plastic materials into usable forms, supporting sustainability in manufacturing.

● Applications: Plastic recycling and reprocessing.

Sometimes, materials may clog or jam inside the extruder, leading to production delays. This is often caused by inconsistencies in material flow or improper feeding.

● Solution: Regular maintenance and inspection of feeding systems can help prevent blockages.

Mesh errors or cooling inconsistencies can disrupt the extrusion process. Proper maintenance of cooling systems and regular mesh checks ensure smooth operation.

● Solution: Adjust cooling settings and mesh parameters to ensure accurate processing.

Improving operational efficiency can be achieved by adjusting screw speed, temperature, and material feeding rates.

● Optimization: Experiment with screw speeds and material combinations to achieve optimal throughput and quality.

Understanding how a PVC Window Profile Machine - Eans Machinery works is crucial for optimizing production efficiency and ensuring high-quality output. Twin screw extruders provide better mixing, higher output, and more flexible material handling compared to single screw extruders. With applications across a variety of industries, including plastics, food processing, and recycling, twin screw extruders are invaluable in modern manufacturing. By selecting the right extruder type and optimizing its settings, manufacturers can achieve greater control over their production processes and enhance product consistency.

WPC door making machine - Eans Machinery offers advanced twin screw extruders, providing solutions that enhance production efficiency, material handling, and product quality. Their products help businesses meet diverse manufacturing needs while ensuring reliability and high performance.

A: A twin screw extruder is a machine that uses two intermeshing or counter-rotating screws to process materials. It's used for efficient mixing, melting, and shaping materials in various industries.

A: In a twin screw extruder, two screws rotate to convey, mix, and melt materials. This results in better material flow, improved mixing, and increased production efficiency compared to single screw extruders.

A: Twin screw extruders offer improved mixing, higher output, and greater flexibility in material handling. They are ideal for processing materials with varying viscosities and offer better control over the extrusion process.

A: A twin screw extruder is preferred when high mixing efficiency, precise material control, or the ability to handle a range of materials is needed, especially in applications like compounding, food processing, and recycling.

A: Common issues include material jamming, mesh problems, and cooling inconsistencies. Proper maintenance, monitoring screw speed, and adjusting temperature can help resolve these challenges.