close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-30 Origin: Site

How much energy does a twin screw extruder use? This is a crucial question for manufacturers looking to optimize operations. These versatile machines are widely used across industries like plastics, food processing, and pharmaceuticals. In this article, we will explore the key factors influencing energy consumption in twin screw extruders. You'll gain actionable insights to optimize energy usage and reduce operational costs.

The energy consumption of a twin screw extruder depends on several critical factors, including motor power, screw design, material properties, processing conditions, and auxiliary equipment. Let's explore these factors in more detail:

Motor power is one of the primary sources of energy consumption in a twin screw extruder. The motor drives the screws, and the power rating typically ranges from 10 kW to 500 kW, depending on the size of the extruder and its intended application. Higher motor power generally means the ability to process tougher or more viscous materials, but it also leads to higher energy consumption.

Tip: Always match motor power with the expected production capacity and material type to ensure optimal energy efficiency.

The design and configuration of the extruder's screws have a significant impact on its energy consumption. The key design features to consider are:

● Co-rotating screws: These screws rotate in the same direction, which increases mechanical resistance and energy consumption but offers better mixing capabilities.

● Counter-rotating screws: These screws rotate in opposite directions, reducing shear forces and power demand, making them more energy-efficient for specific applications like PVC processing.

The screw’s length-to-diameter (L/D) ratio, pitch, and flight depth also influence energy usage. Longer screws with higher L/D ratios need more energy to rotate, but they offer better mixing and higher output rates.

The material being processed plays a critical role in determining energy consumption. Materials with high viscosity, such as engineering plastics, require more energy to process due to the higher torque needed to move and melt the material. Additionally, materials with high moisture content, such as food ingredients, require extra energy for drying or devolatilization during extrusion.

Tip: Preheating materials before feeding them into the extruder can reduce the energy needed to reach the desired processing temperature.

The operating conditions of the twin screw extruder, such as screw speed, barrel temperature, and backpressure, significantly influence energy usage:

● Screw speed: Higher screw speeds can result in higher energy consumption due to increased shear and heat.

● Barrel temperature: Higher barrel temperatures typically require more energy, but careful optimization can minimize unnecessary heating and power usage.

Properly balancing processing conditions can lead to significant energy savings while maintaining product quality.

In addition to the extruder itself, auxiliary components like feeders, cooling systems, and downstream equipment (e.g., pelletizers or cutters) also consume energy. These components can account for up to 30% of the total energy consumption of the entire system.

Tip: When evaluating energy consumption, be sure to account for all auxiliary equipment in your system to get an accurate estimate.

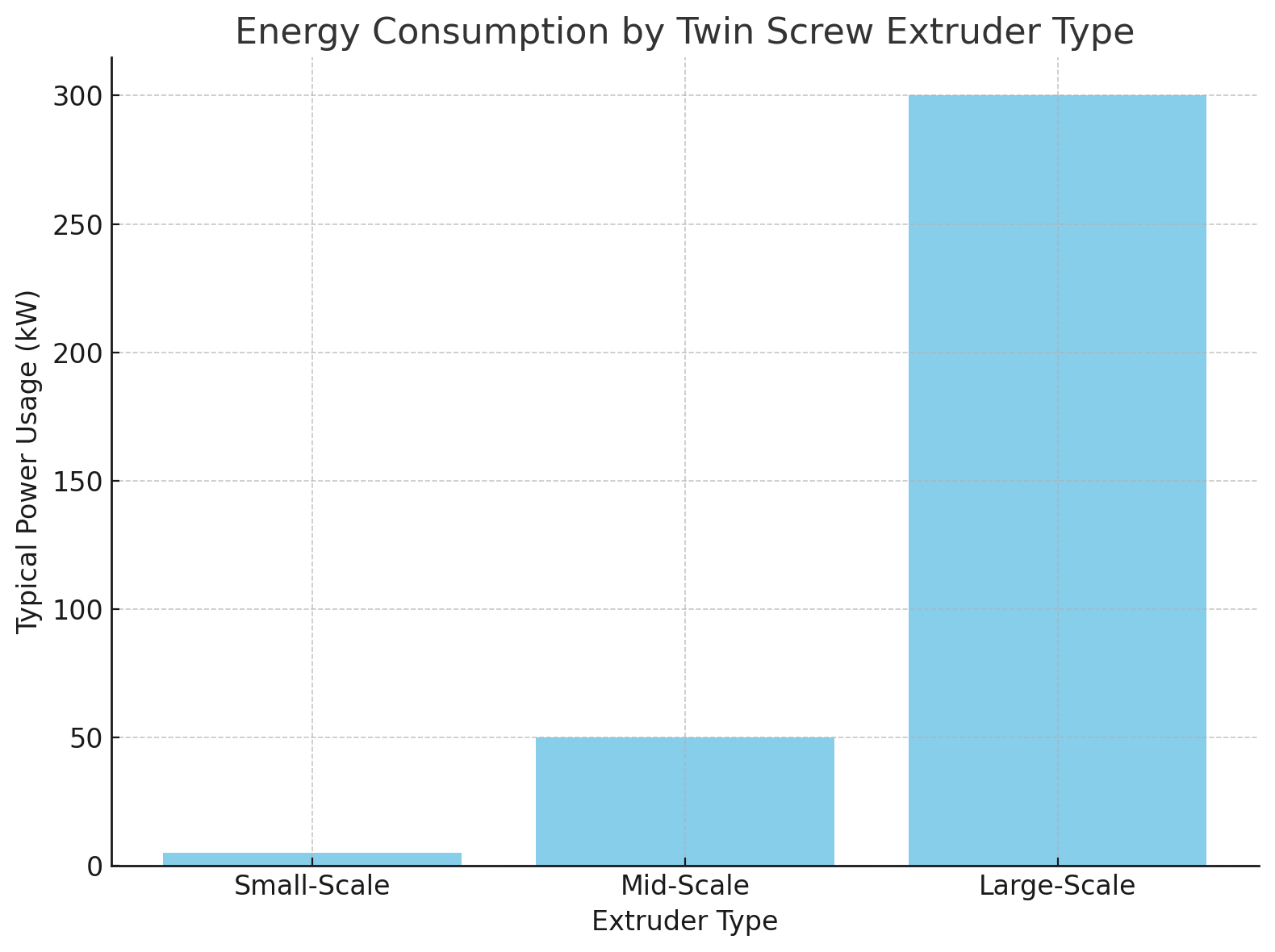

The energy consumption of twin screw extruders varies widely based on size, application, and material processed. Below is an overview of typical energy usage for different extruder types:

● Typical energy usage: 5-50 kW

● Applications: Lab-scale testing, small-volume production, R&D

● Usage: Suitable for low-volume applications where precision is important, but energy demands are relatively low.

● Typical energy usage: 50-300 kW

● Applications: Pet food, snack foods, and moderate volume production

● Usage: These extruders offer a balance between power consumption and output, ideal for medium to high-volume processing.

● Typical energy usage: 300-500+ kW

● Applications: High-output production, reinforced polymer manufacturing

● Usage: These high-power extruders are built for large-scale operations and high-output requirements, processing tough or complex materials.

Estimating the energy consumption of a twin screw extruder involves understanding the relationship between the motor power, operational time, and other factors such as the extruder’s efficiency and material properties.

The motor power rating (in kW) provides an estimate of the energy the extruder requires during operation. To calculate the energy usage, consider the following formula:

Energy Consumption (kWh) = Motor Power (kW) × Operating Time (hours)

For example, if a twin screw extruder has a motor power of 100 kW and runs for 10 hours, it will consume 1,000 kWh during that time.

Specific Energy Consumption (SEC) refers to the amount of energy required per unit of output, typically measured as kWh per kilogram of material processed. The formula for SEC is:

SEC (kWh/kg) = Total Energy Consumption (kWh) ÷ Output (kg)

For example, if an extruder consumes 120 kWh and produces 1,000 kg of material, the SEC would be 0.12 kWh/kg.

Reducing energy consumption while maintaining performance is essential for cost savings and sustainability. Here are some effective strategies for optimizing energy efficiency:

Select screw designs tailored to the material and application to reduce unnecessary shear and backpressure. Efficient screw designs can minimize energy waste by optimizing material flow and reducing torque requirements.

Upgrading to energy-efficient motors, such as those with variable frequency drives (VFDs), can significantly reduce energy consumption by adjusting motor speed based on load conditions.

Preheating materials before they enter the extruder reduces the energy required to bring them up to the desired processing temperature, especially for materials with high moisture content or low thermal conductivity.

Routine maintenance, including cleaning, lubrication, and checking for wear, ensures the extruder operates at peak efficiency, preventing energy losses due to mechanical friction or component failure.

While twin screw extruders generally consume more energy than single screw extruders, they offer significant advantages in throughput, flexibility, and material processing:

● Twin Screw Extruders: These machines consume more power due to their dual-drive configuration and higher throughput but provide superior mixing, better control over material properties, and the ability to handle complex materials.

● Single Screw Extruders: These machines are more energy-efficient but are typically limited in their ability to process complex or high-viscosity materials.

The choice between twin screw and single screw extruders depends on the specific application and material requirements. For complex tasks requiring precision and flexibility, a twin screw extruder may be the better choice despite the higher energy consumption.

The energy consumption of a twin screw extruder depends on several factors, such as motor power, screw design, material properties, and processing conditions. Managing these factors is key to optimizing energy efficiency and reducing operational costs. Manufacturers can also adopt energy-saving strategies, such as using optimized screw designs, energy-efficient motors, and performing regular maintenance. Eans Machinery provides cutting-edge twin screw extruder solutions designed to enhance performance while minimizing energy consumption, offering a perfect balance of efficiency and reliability.

A: The energy consumption of a twin screw extruder typically ranges from 5 kW to 500 kW, depending on the size, motor power, and material processed.

A: Factors like motor power, screw design, material properties, processing conditions, and auxiliary equipment all affect the energy consumption of a twin screw extruder.

A: Yes, optimizing screw design, using energy-efficient motors, preheating materials, and regular maintenance can significantly reduce energy consumption in twin screw extruders.

A: Twin screw extruders consume more energy when processing materials with high viscosity, moisture content, or complex additives due to the increased torque and energy requirements.

A: Twin screw extruders typically consume more energy because they have dual screws that rotate together, creating more shear forces and requiring more power, but they offer greater material flexibility and processing capabilities.