close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-01 Origin: Site

Hot foil stamping machines are revolutionizing industries by adding luxurious metallic finishes. Whether it’s for paper, plastics, or fabric, they elevate product aesthetics.

In this guide, we’ll explore how to use a hot foil stamping machine effectively, ensuring high-quality, durable results. Learn how to master this versatile tool for your production needs.

A hot foil stamping machine is a specialized printing device that applies heat and pressure to transfer foil onto a substrate, creating a glossy, metallic finish. The process involves using a die to imprint foil onto various materials, such as paper, plastics, and even fabric, resulting in crisp, vibrant designs. The key components of the machine include:

● The die: Engraved with the design or logo to be transferred.

● The foil: A thin, metallic film that adheres to the material under heat and pressure.

● Heat and pressure: Activates the adhesive layer on the foil, ensuring a clean transfer.

The process begins by heating the machine to the desired temperature. The die is then placed on the machine’s platform, and foil is laid on top of the material to be printed. The die is pressed onto the foil under heat, causing the foil to adhere to the material and transfer the design. The pressure ensures that the design is clear, sharp, and vibrant. The result is a beautiful metallic design that stands out, adding a premium finish to the product.

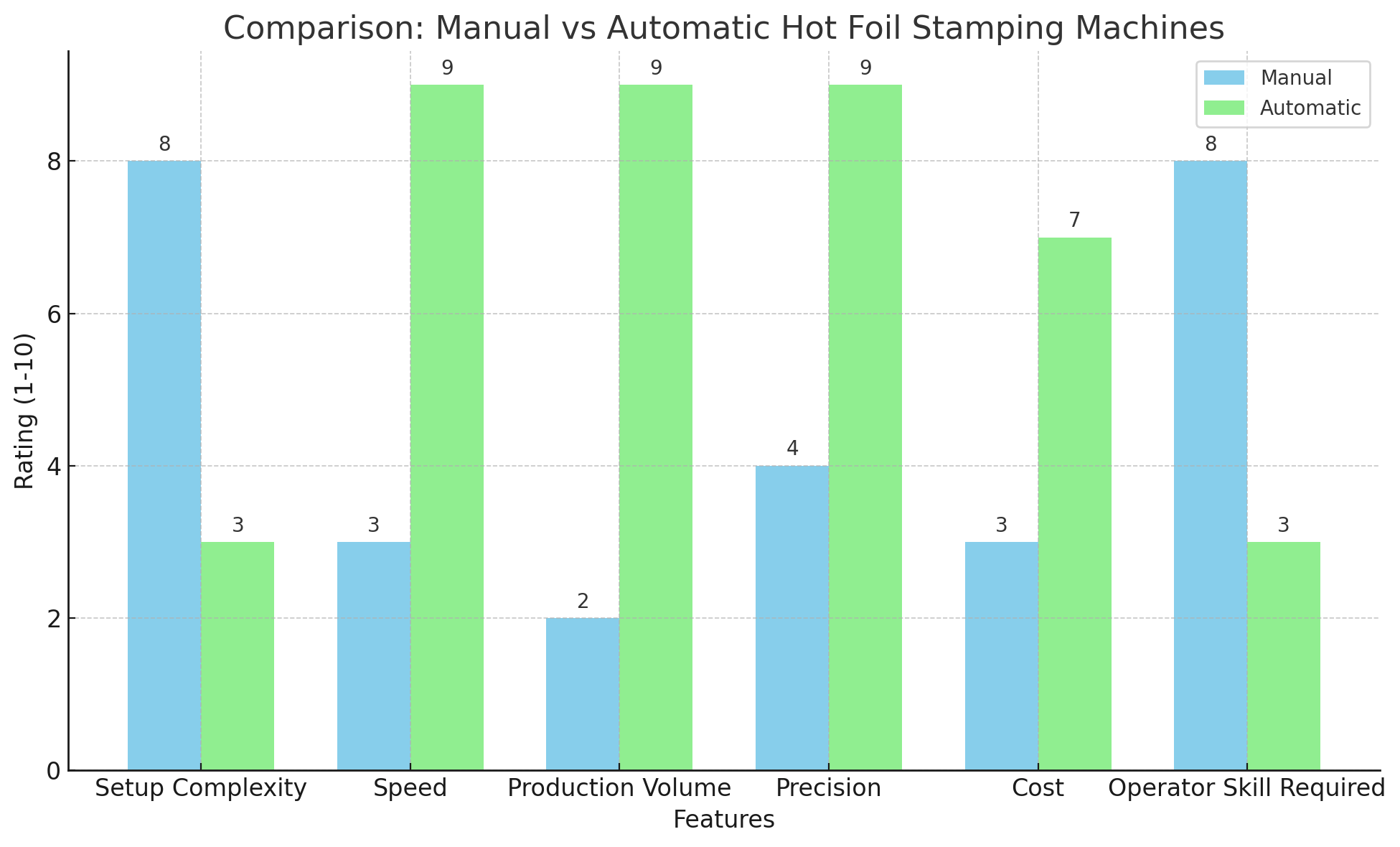

Hot foil stamping machines come in two main categories: manual and automatic.

● Manual machines: Require the operator to control the stamping process by hand. These are best for small production runs and offer more control over individual pieces.

● Automatic machines: Controlled by a computer system that automates the process. These machines are ideal for high-volume production, providing consistency and speed.

The choice of die material can greatly impact the quality and longevity of the stamped design.

● Magnesium Dies: Inexpensive and quick to create, but wear out faster.

● Copper Dies: Offer better durability than magnesium and produce high-quality designs, though they take longer to engrave.

● Brass Dies: The most durable and expensive option, ideal for large-scale production with high precision.

When selecting a hot foil stamping machine, consider:

● Production volume: High-output needs require automatic machines, while small runs benefit from manual machines.

● Material type: Ensure the machine can handle the material you intend to stamp (e.g., paper, plastic, fabric).

● Speed and precision: Automated machines are faster, but manual ones provide more control.

Before starting, ensure the machine is set up properly:

● Set the temperature: Follow the manufacturer’s guidelines for optimal heat settings based on the material and foil type.

● Prepare the die: Ensure the die is clean and properly positioned on the machine.

● Select the foil: Choose the appropriate color and type of foil for your project (metallic, holographic, etc.).

Properly load the material and foil into the machine:

● Position the material: Place the material face up on the stamping platform.

● Cut the foil: Trim the foil to fit the size of the material. Ensure the foil is positioned color side down on the substrate.

The stamping process involves:

● Applying heat and pressure: Place the die onto the foil, apply heat, and press the material and foil together.

● Ensure even coverage: Adjust temperature and pressure to ensure the foil adheres evenly across the material.

After stamping:

● Remove the material: Carefully remove the material from the machine and peel back the foil.

● Clean the machine: Regular cleaning of the die and machine components helps maintain optimal performance and prevents foil build-up.

Inconsistent foiling can be caused by:

● Incorrect temperature: If the machine isn’t hot enough, the foil won’t transfer properly.

● Uneven pressure: Make sure the die applies consistent pressure across the material.

● Foil quality: Low-quality foil may not adhere correctly.

Foil may stick to the die if:

● The die is not cleaned properly after each use.

● The temperature is too high.

Signs of overheating include:

● Foil burning: A burnt or discolored finish suggests the temperature is too high.

● Die damage: Overheating can cause long-term damage to the die.

Hot foil stamping is commonly used for luxury packaging in industries like cosmetics and high-end food products. It adds a sophisticated touch to product packaging, making it more appealing to consumers.

Hot foil stamping is ideal for creating personalized products such as invitations, greeting cards, and corporate gifts. It allows for intricate, custom designs that stand out.

Businesses use hot foil stamping for promotional materials like business cards, brochures, and packaging. The process creates an eye-catching, professional finish that enhances branding.

| Before Foiling | After Foiling |

|---|---|

| Plain card without metallic details | Glossy, metallic design on the card |

| No visual appeal | Embossed logo or intricate design |

Hot foil stamping creates designs with sharp, vivid details that are durable and resistant to fading, providing an elevated finish.

These machines offer high efficiency and can be used with various materials, from paper to plastics, making them versatile for multiple applications.

Investing in a hot foil stamping machine reduces the need for outsourcing and provides long-term savings. It’s an efficient solution for businesses looking to scale their production.

Hot foil stamping is a valuable tool for businesses seeking to enhance their products with a high-end finish. By understanding the machine's process, troubleshooting common issues, and choosing the right equipment for your needs, you can improve the quality and efficiency of your production. Whether for packaging, marketing materials, or personalized gifts, investing in a hot foil stamping machine can elevate your business and products.

Eans Machinery offers high-quality hot foil stamping machines that deliver excellent results, ensuring long-term value and increased efficiency for your production.

A: A hot foil stamping machine is a device that uses heat and pressure to apply metallic foil to materials like paper, plastics, and fabric, creating high-quality, eye-catching designs.

A: To use a hot foil stamping machine, you need to set the correct temperature and pressure, load the die and foil, place the material, and apply heat and pressure to transfer the design.

A: A hot foil stamping machine provides crisp, vibrant finishes, adds a tactile appeal, and is ideal for creating luxurious, professional designs for packaging, invitations, and more.

A: Inconsistent foiling could be due to incorrect temperature, pressure, or foil quality. Ensure the machine is set properly and use high-quality foil for best results.

A: Yes, hot foil stamping machines can be used for various materials, including paper, plastics, fabric, and even leather, offering versatility for different projects.